Hazardous Location Product FAQ

Frequently Asked Questions about the Hazardous Location Products

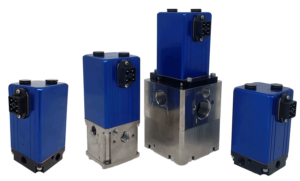

Learn more about our line of Hazardous Location Electro-Pneumatic Pressure Regulators

The Hazardous Location products landing page is located here.

The Hazardous Location products landing page is located here.

ISQBX & ISQBF – These units use the updated configuration of our QBX unit compared to the QBT design. This new design offers a greater availability of components, reducing part shortages and in turn extended lead times. The new units also lack the external side fittings on the legacy products.

ISQB3 & ISQB4 – These units are intrinsically safe versions of our popular QB3 and QB4 units. With these new products we can meet the needs of applications having flows of 1 scfm-200 scfm. In the past to meet this flow range we would pair the ISQB1 or ISF with a dome-loaded regulator. The main advantages of using the new ISQB3 and ISQB4 are accuracy and size. The assemblies we would use in the past required more space and had an accuracy of +/-5% full scale. The new units as complete packages are smaller and have 10X greater accuracy at +/-0.5% full scale.

Aluminum Manifold: Units with an aluminum manifold are compatible with most non-reactive gases, with the exception of oxygen.

Brass Manifold: Units with a brass manifold are compatible with most non-reactive gases and can be used with oxygen as long as they are cleaned in the factory before use.

ISQBF: The ISQBF can be used with a wide range of non-reactive gases and reactive gases. Please contact our Applications Team for more information.

Factory Mutual-Global is an international insurance provider that also has a branch of labs that perform independent research and testing. When a product is undergoes testing by FM and meets certain criteria or standards, it may carry an “FM-Approved” label.

These units offer several characteristics to meet those designations:

- Different printed circuit board (PCB) than our standard line.

- Lower voltage operation to prevent danger of electrical spark.

- Inflammable sealing material added to encase internal components (non-incendive).

- Components and manufacturing process have been inspected by Factory Mutual for meeting the standards they deem necessary to carry the respective “FM Approval” ratings.

These units can be used in a wide range of applications. Some common examples are paint spraying, tank blanketing and fuel pressure testing. They can also pilot dome-loaded regulators in hazardous locations.

The analog pressure transducer effectively measures pressure constantly.

For options other than those that appear in the configuration table, view the How to Order Guide.

Our intrinsically safe and non-incendive products are calibrated at the factory by trained personnel using precision calibration equipment. If one of these products appears to be out of calibration by more than 1%, it is not likely to be the product. Check the system for plumbing leakage, wiring and electronic signal levels. Should the device need re-calibration, the procedure is described in each device’s installation guide. Please contact our Applications Team for more information.

The non-incendive units, ISQBF and ISF1, are internally sealed with non-removable/permanent inflammable material during the manufacturing process. Once assembly is complete these units cannot be disassembled. Since no repairs can be made without comprising the internal components, RMAs are not available.

NOTE: The extent of Proportion-Air’s liability under this warranty is limited to repair or replacement of the defective unit at Proportion-Air’s option.

Email info@proportionair.com for assistance.